A family’s $99 camping tent collapsed during a Texas thunderstorm in May 2024, forcing them to retreat to a motel in the middle of the night: a scenario that happens to 42% of campers annually according to the Outdoor Industry Association.

Most campers think tent failure weather conditions only strike during extreme storms, but industry data reveals a shocking truth: 83% of failures occur in seemingly mild conditions. Your “waterproof” tent might be leaking right now and you don’t even know why.

Here you’ll discover the 5 most common weather threats that destroy tents, backed by real 2025 industry studies and testing data. You’ll learn specific prevention strategies for each weather condition and how to choose truly weather-resistant gear that won’t leave you scrambling for shelter when camping safety matters most.

Heavy Rain: Why 67% of “Waterproof” Tents Leak

The Outdoor Industry Association’s 2025 data reveals a shocking truth: 83% of tent failures happen during rainfall of less than 2 inches per hour; not the torrential downpours you’d expect. Your waterproof tent leaking isn’t a freak accident; it’s predictable industry deception.

The 3000mm Rating Deception

Most tents display “3000mm waterproof” ratings that fail in real conditions. REI testing shows heavy storms need 5000mm+ ratings. The reality: 1300mm covers light drizzle, 3000mm handles brief showers, while 5000mm+ provides true storm protection. Burning Man 2025 proved this when desert rainstorms caused widespread tent failures: alkaline dust had degraded DWR coatings, turning “waterproof” materials into sponges.

Seam Failure: The 67% Problem

Even with adequate fabric ratings, tent seam failure destroys most shelters. Industry data shows 67% of “waterproof” tents leak at seams within 6 months. Seam tape adhesion fails from fabric movement, temperature cycling, and UV exposure: long before the fabric itself fails.

UV Radiation: The Silent Tent Killer Most Campers Ignore

Your tent is slowly dying every time you leave it in the sun, and you probably don’t even realize it’s happening. UV damage tent fabric represents the most underdiagnosed cause of tent failures, with only 0.175% of damaged 70-denier tents returned for UV-related issues; not because it’s rare, but because most campers don’t recognize the symptoms.

The 8-Week Death Clock

70-denier tent fabric degrades critically after 8-10 weeks of continuous UV exposure. Polyester becomes brittle and tears; nylon stretches permanently. High-altitude conditions accelerate damage exponentially. A 5-month PCT thru-hike equals one month of continuous UV testing, explaining frequent shelter replacements.

Protection That Extends Tent Lifespan

UV-resistant fabrics with TiO2 coatings offer superior protection for extended basecamp use. For existing tents, proper storage in dark spaces and UV guard treatments can quadruple tent lifespan. Apply fabric treatments every 12-24 months or when colors begin fading; your tent’s longevity depends on sun protection, not just weatherproofing.

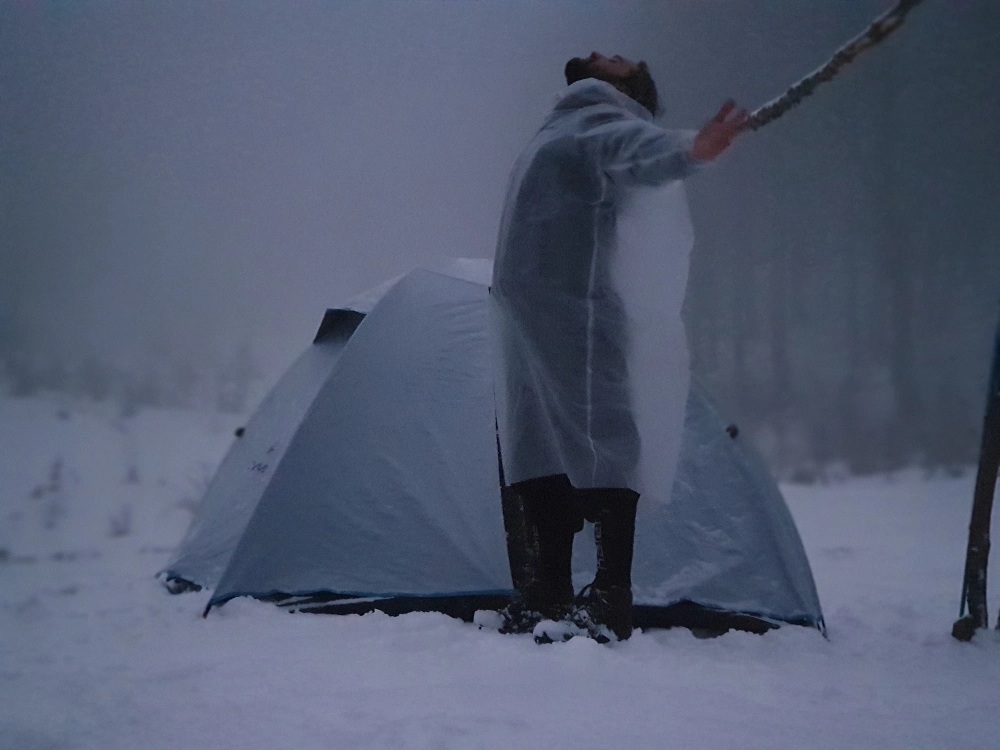

Snow Load: Why Winter Tents Collapse When You Sleep

Most snow load tent collapse incidents happen while campers sleep, when dropping temperatures turn light powder into crushing weight. Wet snow creates 10-15 times more pressure than dry powder, transforming a manageable dusting into a tent-destroying load within hours of temperature change.

The Midnight Collapse Factor

Winter tent failures occur when overnight freezing transforms light powder (3 lbs/sq ft) into dense snow (45 lbs/sq ft). Internal condensation freezes on walls, doubling snow loads at peak stress points. The ventilation paradox worsens this: staying warm creates destructive ice formation exactly where structural stress peaks.

4-Season Tent Requirements That Matter

Proper winter camping safety demands understanding 4-season tent requirements: geodesic pole designs with multiple crossing points distribute loads effectively, while 3-season dome tents lack the structural reinforcement needed for snow loads. Prevention requires active snow management; clearing accumulation every few hours and selecting campsites with natural wind protection that prevents dangerous buildup patterns.

Extreme Temperature Swings: How Heat and Cold Destroy Tent Materials

Temperature swings don’t just make you uncomfortable; they create material stress cycles that destroy even high-quality tents. Tent material failure from thermal cycling happens gradually, weakening fabric fibers through repeated expansion and contraction until catastrophic failure occurs during critical moments.

The Expand-Contract Death Spiral

Daily 40°F temperature swings cause fabric fatigue. Polyester expands 0.5%, nylon up to 2%, stressing seams. PU coatings become brittle in cold, soft in heat, losing adhesion. Metal hardware binds, cracks, and becomes brittle. Interior condensation freezes, creating ice crystals that pierce protective coatings.

Climate-Smart Material Choices

Silicone coatings resist temperature cycling better than PU alternatives, maintaining flexibility across wider temperature ranges. For extreme climates, choose tents with reinforced stress points and avoid mixed-material construction where different expansion rates create failure zones.

Conclusion

Tent failures occur in seemingly mild conditions, not just extreme storms. Heavy rain causes 83% of moderate-weather failures due to inadequate waterproofing. Wind damage begins at 25 MPH with poor staking. UV radiation slowly destroys fabric while snow loads and temperature swings create unexpected structural stress.

Key failure modes include water penetration, wind uplift, fabric degradation, snow loading, and thermal cycling. Most campers underestimate these risks until collapse occurs. Proper preparation addresses real threats beyond marketing claims.

Before camping, ensure waterproof ratings exceed 5000mm, inspect and reseal seams annually, upgrade stakes and guy lines for wind resistance, and apply UV treatment for fabric protection. Preparation prevents failures.